In today’s competitive marketplace, logistics costs can represent up to 10% of the value of goods sold, making efficiency a critical competitive advantage. Warehouses, often the final step before products reach customers, play a vital role in determining productivity, efficiency, cost, quality, and accuracy—essential factors for customer satisfaction.

Despite a surge in industrial space availability in 2023, leasing rates continue to rise, further pressuring companies’ logistics expenses. Optimizing warehouse operations requires a tailored approach, as the needs of a B2C e-commerce company differ significantly from those of a B2B wholesaler. Core processes such as receiving, storing, picking, and shipping vary greatly across different warehouse operating models, from traditional storage to cross-docking operations.

Elements for improving warehouse efficiency

When focusing on optimization, it’s essential to consider the warehouse’s location, layout, inventory management and policies, racking configuration, equipment, process efficiency, safety, management routines, KPIs, performance management, and technology.

<< Read more: Unlocking agile operational efficiency: challenges and rewards >>

For businesses with established warehouses, optimization efforts can concentrate on inventory management and policies, process efficiency, KPIs, and performance management. Effective inventory categorization (Fast, Medium, Slow-Moving SKUs) enhances process efficiency and traceability. Standardizing core processes and continuously improving them are crucial for maintaining operational excellence and addressing the diverse workforce typically found in warehouses—often made up of several contractors, seasonal employees, and new hires.

Applying supply chain optimization in warehouses

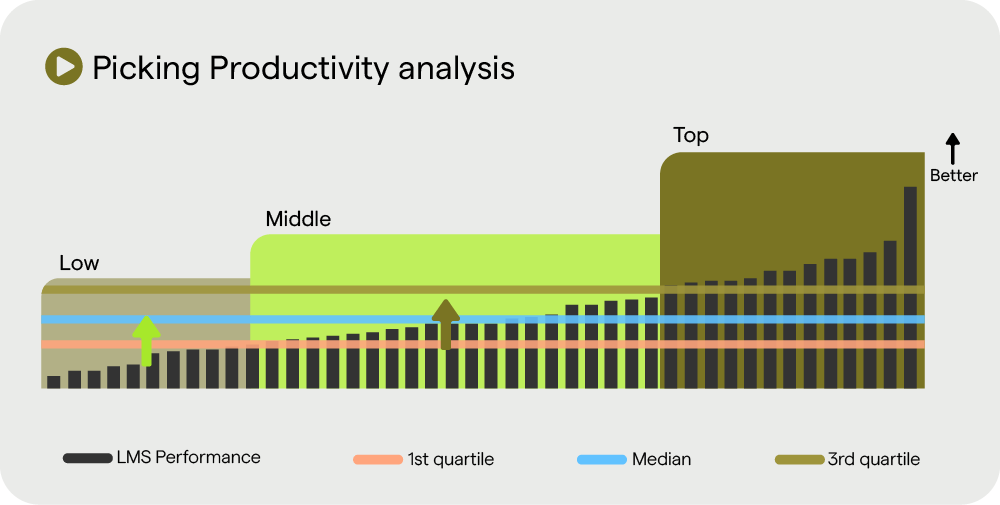

Success stories from Falconi’s extensive experience in supply chain optimization highlight the benefits of focused improvements. For example, a global food and beverage company realized annual personnel savings of $152,000 by standardizing a single picking process across warehouses—a simple yet effective strategy. Below, an initial analysis of picker productivity shows significant variability within one picking process in one warehouse:

<< Read more: Benefits of digital transformation in manufacturing industry >>

Similarly, Falconi helped an agricultural company significantly reduce inventory levels and obsolescence costs by rationalizing SKU categories, resulting in a $2.66 million reduction in inventory levels and a $700,000 decrease in inventory obsolescence. Through simple grouping of SKUs into seven distinct categories from “Very High Turnover” to “Low Turnover, High Cost,” and aligning safety stock and storage policies accordingly, most of the problem was alleviated.

<< Read more: Demystifying operational excellence in asset-intensive sectors >>

For companies with reasonable levels of data availability and quality, Falconi’s technology has delivered more than 50 success cases using AI and machine learning applications, several of which achieved a simultaneous reduction of inventory levels while increasing sales.

Unlocking the potential of your warehouse for operational excellence

In the face of ongoing supply chain disruptions, labor market tightness, and inflation, every efficiency improvement counts. Prioritizing warehouse operations is key to navigating changing market dynamics, ensuring reliability, and building a foundation for sustained success.

Today’s fast-paced market means operational excellence isn’t just an advantage—it’s a necessity for thriving in today’s market. Falconi is ready to support your business on its operational excellence journey, ensuring warehouse operations are optimized for efficiency and resiliency.

Matt McCabe